Take an armchair visit to a unique brewery, pub or other intoxicating venue that has a story you’ll love.

Yakima Valley Hop Harvest:

Visiting the Yakima Valley hop harvest provided one of the most unique interactive, beer-related experiences that my wife and I have enjoyed together. Located in central Washington State, Yakima Valley houses an extremely productive agricultural industry noted for apple, wine and hop production. And according to the USDA, Washington produced 73 percent of the United States hop crop for 2019. Hence, Washington State and Yakima Valley hop production is critical to beer production.

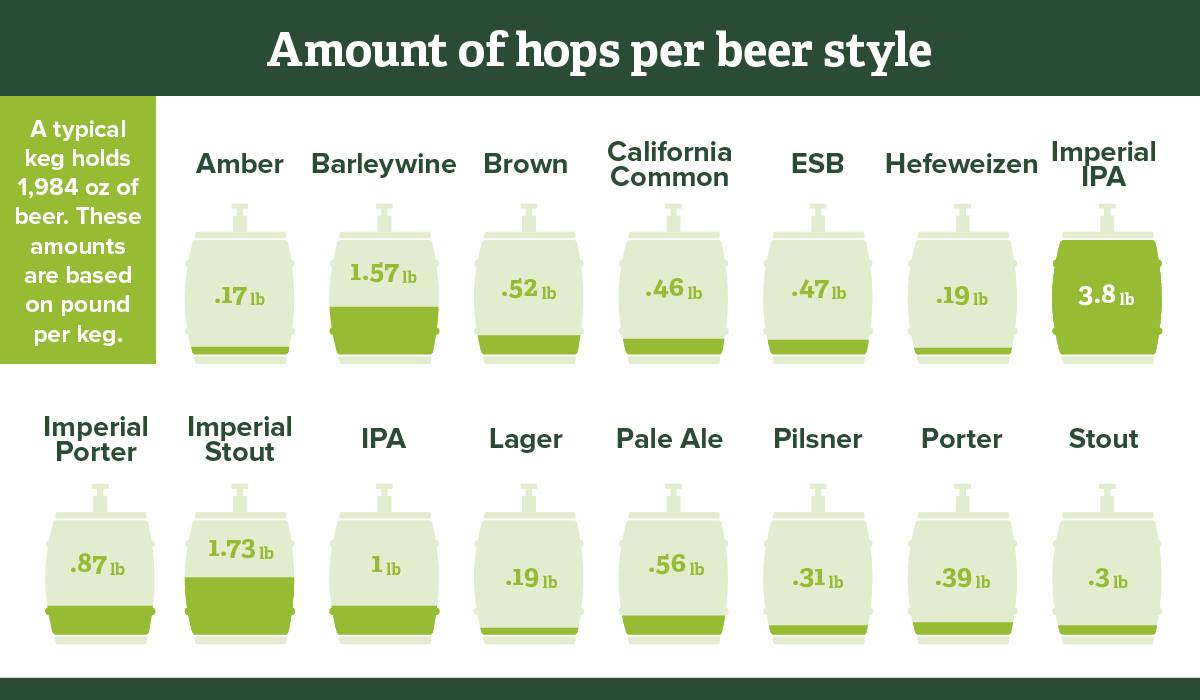

Infographic courtesy of Hop Growers of America

Infographic courtesy of Hop Growers of America

Hop harvesting in this region begins in late August and continues through September. During this time period, brewers throughout the nation visit Yakima Valley to evaluate the hop crop quality and complete purchases for their next year’s beer production.

We visited the Loftus Ranches hop farm and hops processing facility. Established in 1932, B.T. Loftus Ranches Inc. is one of Yakima Valley’s longest running hop farms. In 1920, the Loftus family moved to Moxee (a city in Yakima County) in pursuit of work on the railroad and began farming a variety of crops and livestock. Twelve years later, B.T. and Leota Loftus established the family’s first nine-acre hop field. Today, third and fourth generation hop farmers Mike and Patrick Smith own and operate Loftus Ranches.

One of the largest hop growers for the craft beer industry, Loftus Ranches dedicates themselves to growing hop varieties that meet the needs of brewers for many years to come. Co-owner Mike Smith graciously granted us full access to the farm and processing facilities. We followed an empty truck returning to the fields where harvesting was ongoing to watch the harvest in action.

Hop Harvest and Processing

Here’s a summary of the hop harvest and processing activities we followed.

- Commercial hop plants grow on trellises specifically designed to maximize growth and allow equipment harvesting. We witnessed the harvesting of Mosaic hops. These hops filled the air with rich aromas of berries, mango, citrus, earthy pine, tropical fruit, and stone fruit. The smell was intoxicating!

A typical commercial hop farm requires about 600 acres of planted land.

A typical commercial hop farm requires about 600 acres of planted land.

- Once ready for harvesting, workers cut the bine at the base of each plant. Unlike vines, which use tendrils, suckers, and other appendages for attaching themselves, bines use stout stems with stiff hairs to aid in climbing. Automated equipment known as a Hop Top Cutter then cut the top of the bine from the 18 foot high wire. The Top Cutter is a front mounted sickle blade that quickly cuts the guide strings at the top. A truck trailer stays close in front of the cutter allowing the bines to fall nicely into the trailer for further processing. The cutting process occurs at an approximate pace of an acre per hour.

Top Cutter at left and following trailer truck in right 3 images.

Top Cutter at left and following trailer truck in right 3 images.

- Sometimes bines fall to the ground and workers need to pick them up and add them to the truck.

Picking up bines from the ground.

Picking up bines from the ground.

- Trucks then carry the cut bines to a processing facility. Once cut the hop plant cones need to be processed and begin drying in a few hours at the absolute maximum (preferably within 1 hour).

During hop harvest season the roads can be very busy with trucks.

During hop harvest season the roads can be very busy with trucks.

- Workers place the bines on conveyor belts that pass the bines through equipment for separating the hop cones from the leaves and bines.

Workers connect each bine to the conveyor.

Workers connect each bine to the conveyor.

- A conveyor belt transports the separated cones to another building for kiln drying. The freshly harvested cones contain 80 percent water and would rot or mold quickly if they were not spread across a kiln, heated with natural gas burners, and allowed to dry for about 10 hours. After drying, the cones contain about nine percent moisture.

Kiln drying for processing.

Kiln drying for processing.

- Dumping the dried cones onto another conveyor belt sends them to a warehouse for further processing. Workers pour or compress cones to be sold as whole cones or made into pellets for delivery (once sold) to brokers or breweries.

Hop pellets.

Hop pellets.

The entire process takes about 24 hours.

During the hop harvest time period many breweries, especially those near hop farms, like to create “Fresh Hop” beers. Fresh Hop beers are made using freshly picked hops that have not been dried. These hops need to be inserted into the brewing process within 24 hours of being picked. When properly created, Fresh Hop beers offer fantastic aromas and flavors.

Our time spent shadowing the hop harvest and processing made for an exciting, fun day.

We even managed to leave with a new car air freshener.

We even managed to leave with a new car air freshener.

This had to be the best, most intense experience in our travels. The smell of the hops was intoxicating. It outranked driving through groves of oranges or almonds in bloom. I fell in love with beer this day.